Our service for your needs

Discover our wide range of services

We offer you:

Consulting:

Our experienced team will be happy to support you on your journey from the vision to the finished plastic product or assembly.

Process development:

With extensive expertise and many years of experience in the industry, our focus is on process development. This enables us to ensure that every phase of your project is optimally tailored to your needs. By using computer-aided simulations, we can identify potential risks in the early stages of the process and thus maximize the efficiency and quality of our solutions.

Prototype development:

In the initial phase of your project, we offer you targeted support by providing prototypes – tailored to your needs and ideas. Depending on the specific requirements of your application, these prototypes can be produced either by 3D printing or by injection moulding using specialized prototype tools .

In this way, we ensure that you receive valuable feedback on your product at an early stage and can make adjustments.

Die-cast aluminum replacement:

“When aluminum becomes more expensive – plastic injection molding becomes smarter! Lighter! More sustainable!”

We can look back on decades of experience in aluminum die casting replacement – including pressure housings that can withstand a burst pressure of 150 bar. The supply of aluminum in Europe is currently under pressure – dependence on imports and increasing uncertainty in the supply chains, high energy prices and customs duties are causing material and production costs to rise significantly.

Switching from die-cast aluminum to plastic components offers an economical and sustainable alternative – with comparable or even better performance. Plastic injection molding impresses with its lower weight, high design freedom and significantly reduced CO₂ emissions. With our comprehensive materials expertise and project experience, we can support you from the initial idea to series production and develop the optimum substitution concept for your component.

Bring us your current aluminum die-cast part! Together we will analyze how you can fully exploit the advantages of plastic injection moulding with our know-how – cost-efficient, future-proof and sustainable.

Our services at a glance

- Technical advice and practical support during the implementation phase

- Injection molding simulation based on customer data

- 3D printing of patterns

- Prototype tools for test parts

- Statistical design of experiments (DoE) for process optimization

Consulting:

Our experienced team accompanies you from the vision to the finished plastic product or assembly.

Development/process development:

We focus on process development to achieve optimum results in every phase of your project. Computer-aided simulations help us to identify risks at an early stage and increase quality.

Prototype development:

We provide prototypes in the initial phase of your project. Depending on requirements, these can be produced using 3D printing or injection molding with prototype tools. In this way, you receive valuable feedback promptly and can make adjustments.

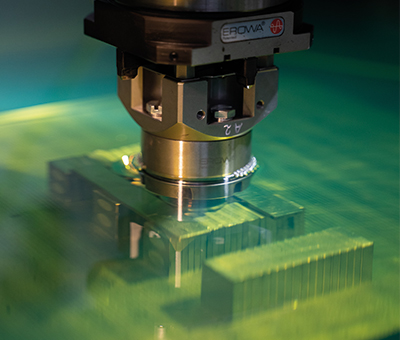

We ensure the consistent quality of our high-quality injection molds thanks to our state-of-the-art toolmaking department. This offers us maximum flexibility in tool maintenance, spare parts production and even the complete construction of injection molds.

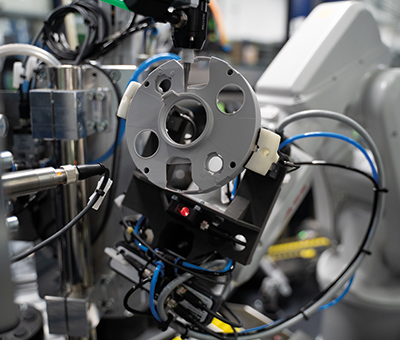

Toolmaking is supplemented by our special machine construction, in which product-specific production automation can be manufactured.

- CNC milling (high-speed milling with 5 axes)

- CNC erosion machines

- Wire erosion machine

- CNC automatic lathes

- Copy grinding machine

- Surface grinding machine

- Cylindrical grinding machine

(inside/outside) - Contour grinding machine

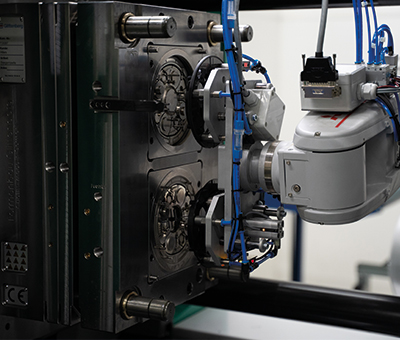

With our modern machinery of over 80 plastic injection molding machines, we process almost all thermoplastics into high-quality injection molded parts.

We have machines with clamping forces of 150 kN to 5,500 kN in single and multi-component technology at our disposal.

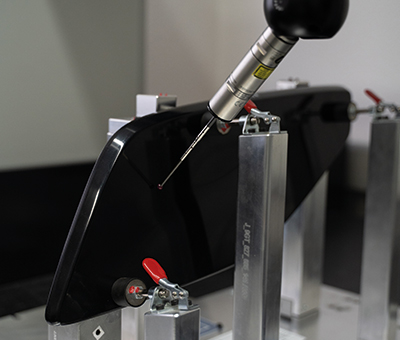

Immediate product finishing or testing can be carried out immediately using individual automation technology on the injection molding machine.

- Clamping forces from 150-5,500 kN

- Removal and packaging with fully automated robots

- Single and multi-component technology

- Inlay technique

- Fabric overmolding

- 100 % inline testing

Depending on customer requirements, the degree of automation of product finishing can range from manual assembly to fully automated component assembly.

- Leak tests

- Ultrasonic and vibration welding

- Gluing

- Printing

- Heat sealing

- Proper storage

- Fast availability and reliable delivery

- EDI interfaces

- Labeling according to customer requirements

- 3,500 m² storage capacity

- FiFo

- Consignment warehouse

- Just in time

- Just in Sequence

Unsere Referenzen